VISION AND GROW

About Industry

TeamMaxiGrip

SMART SOLUTION WITH ENGINEERING & INDUSTRY

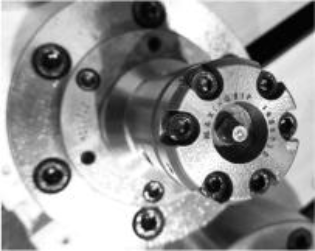

Maxi Grip's engineers' have immense experience in manufacturing technique and methodology. This experience allows us to take your requirements and work closely with your team to design and develop a custom solution that precisely meets your needs.

In April, 2018, the company was taken over by RENS under the leadership of Sagar Sheth and Nathan Brower. With this acquisition, the company transformed through lean manufacturing principles, improved capability and engineering advancements to help the company evolve into a modern, fast paced manufacturing and design facility.

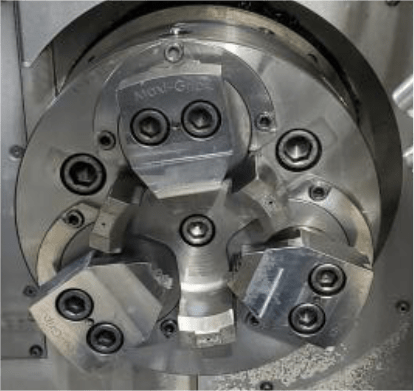

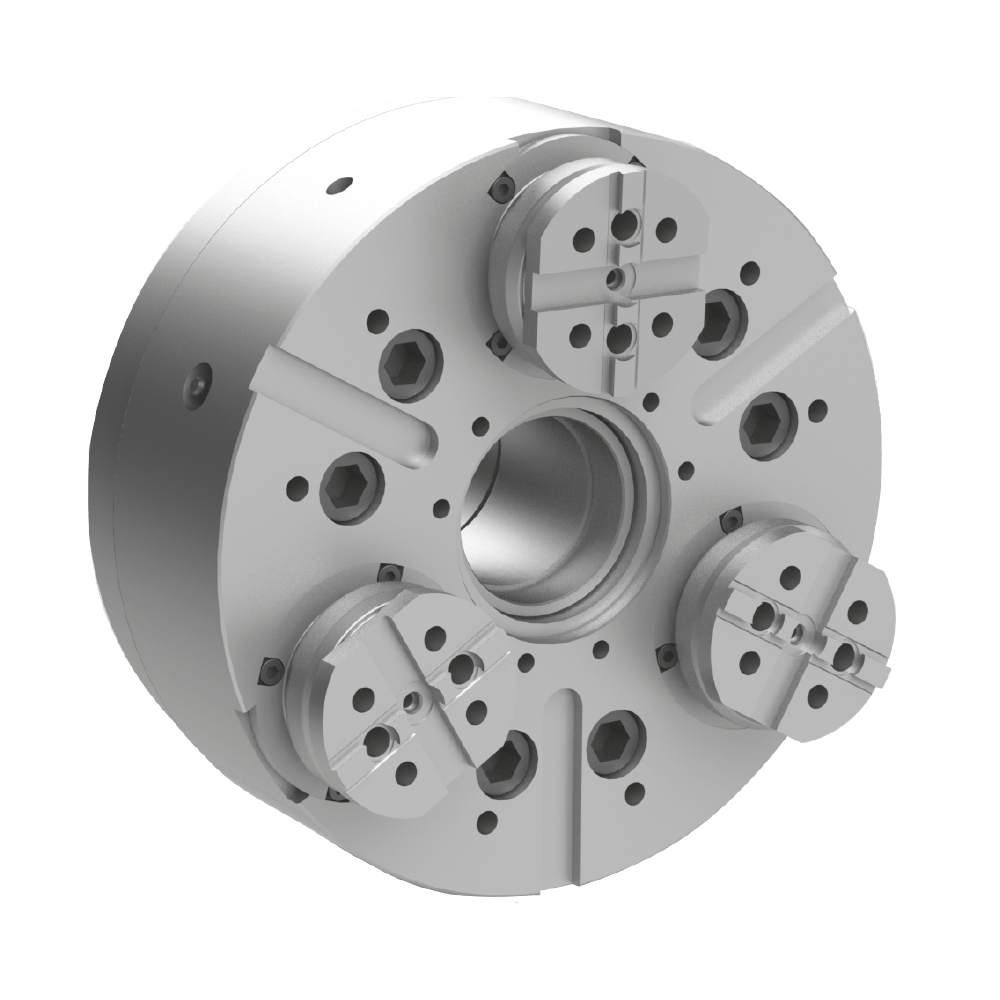

In the development of turnkey solutions, the company has improved it’s offering to better support our customers in the area of robotics and automation. This transformation has put Maxi Grip back on the map as a disruptive force in the workholding space specializing in smart chucks and end effector technology.

Through their leadership and direction, the company grew to serve over 120 customers worldwide in automotive, aerospace, medical, agriculture and military with offerings of over 42 different types of chucking and workholding solutions.

"I have been using Maxi Grip workholding for years, their innovative design and manufacturing solutions has increased our efficiency time and again"

MAXI GRIP SOLUTIONS

ABOUT COMPANY

new Place for Better Innovation industry

Integrated Approach

Maxi Grip’s engineers’ have immense experience in manufacturing technique and methodology. This experience allows us to take your requirements and work closely with your team to design and develop a custom solution that precisely meets your needs.

COMPANY ADDRESS

24871 Gibson Drive Warren, MI 48089

WHY CHOOSE US

Let's start your project to be realize

Recognized worldwide in automotive, aerospace, medical, agriculture and military with offerings of over 42 different types of chucking and workholding solutions.

EXPERT Employees

Certified Technician

24/7 Support

Top Quality

RESOURCES

TARGET ORIENTED

OUR SERVICES

Building Maxi Grip For The 21st Century

The many duties and operations relating to hydraulic systems are referred to as hydraulic workloading services. Typically, these services are offered by specialized businesses or individuals with knowledge of hydraulic engineering and machinery. Various hydraulic workloading services are available, based on the particular requirements and uses. The following list includes several typical hydraulic workloading services:

Hydraulic System Installation:

Hydraulic workloading services may involve the installation of hydraulic systems following the design phase. Fitting and connecting components such as pumps, valves, actuators, hoses, and reservoirs in accordance with the authorized design is required.

Hydraulic System Repair:

In the event of a system breakdown or malfunction, hydraulic workloading services may include repair and troubleshooting efforts to determine the root cause and resolve the issue. This may entail replacing damaged components, repairing leaks, or modifying system settings.

Hydraulic System Design:

This entails the engineering and design of hydraulic systems for a wide range of applications, including industrial machinery, construction equipment, and aircraft systems. Selecting appropriate components, calculating system parameters, and ensuring efficient and dependable operation are all part of the design process.

Hydraulic System Maintenance:

Hydraulic systems must be serviced on a regular basis to maintain good operation and lifetime. Fluid replacement, filter replacements, system inspections, and troubleshooting to detect and resolve possible faults are examples of maintenance services.

CLIENT SAY

TRUSTED AROUND THE WORLD 120+ COMPANY FOR AWESOME PROJECT

Rest Assured Guaranteed that every Maxi Grip product is

guaranteed to perform as designed to your requirements or we will fix it.

Donec id elit non mi porta gravida at eget metus. Vivamus sagittis lacus vel augue laoreet rutrum faucibus

Hendrik Morella

NAME COMPANY

Donec id elit non mi porta gravida at eget metus. Vivamus sagittis lacus vel augue laoreet rutrum faucibus

Carryn Zenith

NAME COMPANY

Donec id elit non mi porta gravida at eget metus. Vivamus sagittis lacus vel augue laoreet rutrum faucibus

Danielle Soca

NAME COMPANY